|

Hebei Clean & Clear Glass Co.,Ltd

|

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Material Introduction

Borosilicate glass is a type of glass with the main glass-forming constituents silica and boron oxide. Borosilicate glasses are known for having very low coefficients of thermal expansion(~3 × 10−6 /°C at 20°C), making them resistant to thermal shock, more so than any other common glass.

In addition to the quartz, sodium carbonate, and aluminum oxide traditionally used in glassmaking, boron is used in the manufacture of borosilicate glass. The composition of low expansion borosilicate glass such as those laboratory glasses mentioned above is approximately 80% silica, 13% boric oxide, 4% sodium oxide, and 2-3% aluminum oxide. Though more difficult to make than traditional glass due to the high melting temperature required, it is economical to produce. Its superior durability, chemical and heat resistance finds excellent use in chemical laboratory equipment, cookware, lighting and, in certain cases, windows.

Borosilicate Glassware Features and Advantages

1,they are heat resistant,suitable for use in microwave,dishwasher and stove

2,offer a variety of application possibilities: baking and cooking, preparing and serving, cooling and freezing (down to -35°C/-31°F)

3.show a high resistance to sudden temperature changes with a temperature difference of 140°C/284°F(three times as high as normal glass or lead crystal glass)

4,are produced from clear borosilicate glass which is free of smell and flavor,does not discolor and show high chemical and mechanical resistance

5,do not give off any substances and therefore are suitable for allergy sufferers

Present market Glasswares Grades

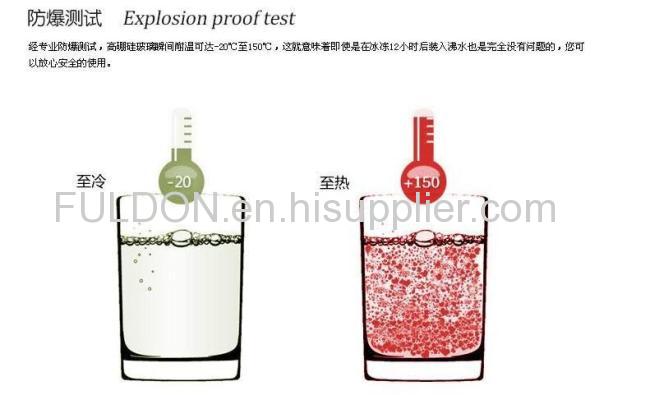

Top Quality High borosilicate glass: is approximately 80% silica, 13% boric oxide, 4% sodium oxide, and 2-3% aluminum oxide. It show high resistance to sudden temperature changes with a temperature difference of 170°C(-20°C---150°C)

Recycled borosilicate glass: with less than 20% silica,and contaminated to environment and human body

Normal Glass:contains too many complicated impurities and with machine mass production

C&C Glass products are all made of top quality high borosilicate glass,with superior heat resistant and eco-friendly quality

Why choose C&C Glass

1. All our products are able to endure sudden temperature changes from -20°C to 150°C in extremely short time

Questions: Are this kind of glass wares safe ? Does they easily broken and fragile ?

Answers: Borosilicate glasses are known for having very low coefficients of thermal expansion(-20°C--150°C), making them resistant to thermal shock, more so than any other common glass.In addition,it is much lighter in weight but more solid in molecular structure,thus even with small thickness,it also could reach high strong intensity and so more durable than traditional soda lime glass.

C&C Glass uses high quality borosilicate glass and pay more special attention to the thickness of products,make them thicker but firm and comfortable when you hold them.Therefore,C&C products are one of the most safest and popular products in the market

2.Sophisticated Hand Blown Craftsmanship,Uniform Mold 3.As a more advanced glass material,Borosilicate glass were widely used in Chemical and Medical industry and High end Kitchenware in most European and American countries.With sophisticated mouth blown craftsmanship,workers needs to constantly rotate the glass embryo in order to heat the glass uniform.This is the most significant special features of hand made glasswares compared with other glassware

3.As a more advanced glass material,Borosilicate glass were widely used in Chemical and Medical industry and High end Kitchenware in most European and American countries.With sophisticated mouth blown craftsmanship,workers needs to constantly rotate the glass embryo in order to heat the glass uniform.This is the most significant special features of hand made glasswares compared with other glassware

Production Flow